FAQ

Drips in the paintwork can arise for a number of reasons:

- To avoid them, you should always ensure that your spray distance to the object is never too low. It should always be at least 15 - 25 cm.

- Also, the paint should not be applied too thickly in one go. Spray on several thin layers in cross-coats. This involves applying a horizontal coat first and then a vertical coat. The turning point should be external to the object

- Also, care should be taken to ensure that all work materials, such as the spray paint can, the object that is to be painted and the room temperature are all at the ideal processing temperature which lies between 20 and 25°C.

- If no primer is used when painting plastics, the paint will flake the first time it is put under pressure. The paint will not adhere to most plastics which is why a plastic primer should be used.

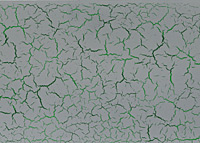

- Also, cracks can appear in the paint if for example a highly pigmented paint, e.g. a primer, is applied to a less pigmented paint, e.g. a top coat.

- The paint structure should there fore comply with the following pattern: Primer - base paint - clear lacquer

- Also, cracks may appear in the paintwork if a number of different paint types has been used. One product line from the same manufacturer should always be used for the whole paint structure to avoid any incompatibility problems.

- Due to the fact that the spray distance is too great, the paint does not run on the surface any more. It already dries in the air and lands as “spray mist“ on the surface. This can be avoided when the painting distance of 15 - 25 cm is maintained constantly.

- A further reason for this may be that the paint is applied to an object that is too hot or the paint is applied in bright sunshine. If the heat is too great, the solvent on the surface can no longer be released and “bubbles” are created which then prevent the surface from shining. This can be avoided by only painting in a place protected from the sun with the ideal processing temperature of approx. 20 to 25°C, at low humidity.

- Also the paint shine can be impaired by dust in the air – always apply the paint in a protected place.

- Creases are created when for example the paint “lifts”

- If a synthetic resin paint is painted over with a different type of paint or with itself after it has dried, it will lift and/or form creases. Synthetic resin paints are oxidative drying paints, i.e. they dry in the air. It takes approx. 6 hours until the top layer of paint has dried. After this time the paint should no longer be painted over as a new coat of paint and therefore the re-application of solvents will make the lower paint layers swell.

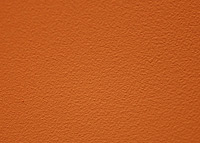

- This painting result is created when the spray distance is too great. The paint that has already dried in the air, the so-called “spray mist“, is deposited on the surface and does not run any more. At the start, the surface is just rough and matt. After a thicker layer of paint, dents are formed, so-called “orange peel skin“.

- This can be avoided when the spray distance is a constant 15 - 25 cm and the painting temperature lie between approx. 20 and 25°C.

There are a number of reasons for this:

- On the one hand this may occur if the spray paint can is not shaken for long enough. Before spraying, the spray paint can should be shaken for at least 2 min., starting from the moment when the mixing balls can be heard. This is necessary as the pigments settle on the bottom of the can during storage.

- Another reason may be that the paint used does not cover well and therefore too little paint is applied and the primer shimmers through and distorts the colour tone.

- Likewise, it may be a result of the painting method itself. In the case of metallic paints, the painting result depends on the spray distance. If the spray distance is too small, the colour tone will be too dark. If the spray distance is too great, the final result is too light. To avoid this, first perform a spray test and compare the colour tone. The ideal spray distance is approx. 15 - 25 cm.

- The fresh paint is applied and stored at temperatures that are too low. At temperatures below 20°C, the air dries the paint more slowly e.g. for NC/AC paints, because the drying process involves the evaporation of the solvent. The drying process depends on the temperature. The colder it is, the slower the solvent will evaporate.

- Otherwise, it may be a silicone resin paint – usually used for heat resistant paints. This needs to be heated slowly so that it dries completely.

The 2-coat paint system is being used more and more in the automotive industry for metallic colour tones. In order to repair this paintwork in exactly the right colour tone, a 2-coat paint system is used; a base paint that needs to be painted over with a 2-coat clear lacquer is used as a colour component. The top coats are marked by their good covering properties. However they are matt and not weather resistant before they have been coated with the 2-coat clear lacquer.

(=2 components) These are all products that are hardened/dried by adding a hardener. For spray paint can technology, this means: The paint and hardener are combined in one spray paint can. The hardener is in a separate container that is released at the press of a button and mixed with the paint. The 2-component system is particularly sturdy and resistant to scratches and weathering and also guarantees excellent product quality.

A spray can should be used until no more product comes out when the spray head is actuated comes, only then is the can completely emptied. Empty spray cans are collected via the recycling facility (Yellow sack, container for light packaging e.g.) recycled. Cans with contents are to be disposed of as hazardous waste.

Petrol and chemical resistance

- 2K (2-component) paints have a high resistance to petrol and chemicals.

- Our paints used in the "Auto-K" area are 1K (1-component) products.

- These are mostly weather and UV resistant, but only partially or not sufficiently resistant to petrol and chemicals.

Tip: If, however, e.g. a few drops of petrol get onto the paint surface, dab them off immediately with an absorbent cloth or cotton cloth. Never rub or rub in.

Benzin- und Chemikalienbeständigkeit

- 2K (2-Komponenten)-Lacke weisen eine hohe Benzin- und Chemikalienbeständigkeit auf.

- Unsere im Bereich „Auto-K“ eingesetzten Lacke sind 1K (1-Komponenten)-Produkte

- Diese sind meist Witterungs- und UV-beständig, aber nur bedingt bzw. nicht ausreichend Benzin- und Chemikalienbeständig

Tipp: Sollten dennoch, z.B. einige Tropfen Benzin, auf die Lackoberfläche gelangen sind diese umgehend mit einem saugfähigen Lappen oder Baumwolltuch abgetupft werden. Auf keinen Fall verreiben oder einreiben.